Book a demo

The consistent increase in data for all modern companies is one of the most important recent drivers towards the digital transition. Companies that do not yet collect data from their internal and external processes and for the various business units (from production to administrative offices) are destined to lag behind in the global competition.

At the same time, companies that have equipped themselves with modern machinery and latest generation sensors, which generate data relating to all the company's activities, realize that these data need to be further enhanced, compared with each other, and structured to obtain valuable information for the individual business. Among the most widespread enabling technologies, the Internet of Things (IoT) plays an increasingly important role.

The applications made possible by the IoT are many:

An industrial machine connected to the network, in fact, constantly releases data and information relating to a series of parameters (speed, energy consumption, oscillations, etc.) that can be used to optimize the production process, making it more efficient.

Doing industry, in the current economic and global context, is much more complex than in the recent past: consumers require less and less standardized products, and demand is characterized by little linearity and the presence of peaks. In the background, finally, there is a growing competition of actors from developing countries.

At the same time, environmental regulations are being strengthened, requiring producers to pay further attention to the characteristics of their production process.

In this context, the industrial machines necessary for production are required - on the one hand - to operate at a fast pace, in order to respect delivery dates, and - on the other - to possess the right degree of flexibility to respond to any input. external.

There are also indirect costs, but no less important: they are production stops for example, which can result in delays in deliveries, not to be underestimated in times of globalization and increased competitiveness. Finally, it is important to underline the importance of integration between production systems and systems dedicated to management (ERP): the former, in fact, are often in line with the commercial and accounting part, but not integrated for Planning and production ( MES).

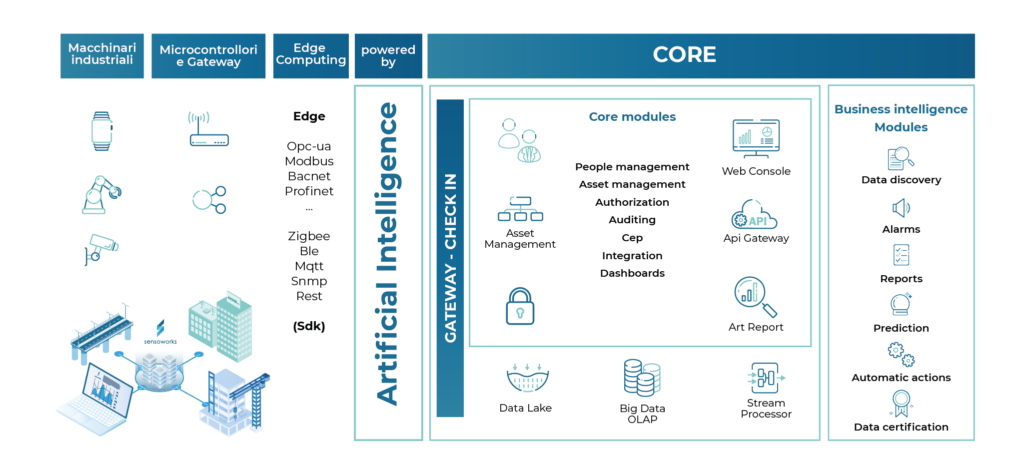

The Sensoworks I-IoT platform includes all the components that make the connection to the machinery and, in general, to all the objects to be monitored in the IoT world (machinery, sensors, production line trolleys, final production products, etc.) .

The platform can be logically divided into two areas:

What are the functional benefits of the Sensoworks platform?

The functional advantages can be translated into Operational Benefits for the company:

In light of a fertile scenario of opportunities and digital innovations such as the one described, the need for technological support in the company is evident, capable of optimizing processes, identifying processes to streamline and sometimes even new business models more suited to new business habits. consumption.

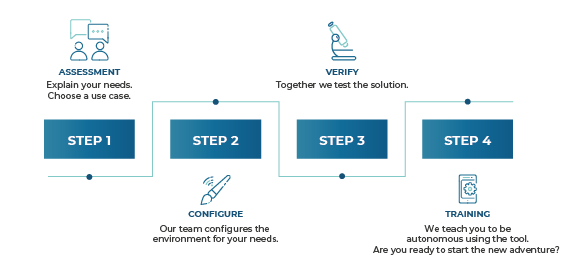

Sensoworks is the ideal partner, able to offer targeted solutions for companies that want to start their digital transition path. To simplify the adoption of new technologies, Sensoworks has created a synthetic adoption plan, which ends in just 4 days from the start of the process, and makes the company completely independent in the use of its digital platform.

DO YOU WANT TO KNOW THE NEXT STEPS?

Book an appointment with Eleonora Stragliotto, Head of Sales in Sensoworks (link to calendar). Choose the days and times that are most convenient for you directly on the calendar.

DOWNLOAD OUR PAPER (link)

If you want to deepen the subject with other technical details, download our paper, entirely dedicated to the digital transition and solutions designed for industry 4.0.